Why Does My Air Compressor Not Shut Off

Your air compressor may not shut off due to a faulty pressure switch or a leak in the system. This can cause the compressor to continuously run, reducing its efficiency and potentially causing damage.

Ensure the pressure switch is functioning properly and inspect the system for any leaks to resolve the issue. An air compressor is an essential tool used in various industries and applications. It provides compressed air to power equipment and machinery, making it a crucial component in many operations.

However, if you notice that your air compressor is not shutting off, it can be concerning and indicate a problem. We will explore the potential reasons why your air compressor is not shutting off and provide insights on how to address this issue. By understanding the underlying causes, you can take the necessary steps to rectify the problem and ensure your air compressor operates efficiently.

Credit: www.teamaircenter.com

Understanding The Working Of An Air Compressor

If your air compressor does not shut off, it may be due to a faulty pressure switch or an air leak in the system. Check the pressure switch for any issues and inspect all connections for leaks to determine the cause of the problem.

An air compressor is an essential tool that is used in various industries and applications. If you’re wondering why your air compressor does not shut off, it’s important to understand how it operates and the components involved. By gaining insights into the inner workings of an air compressor, you can troubleshoot the issue more effectively.

Let’s dive into the details:

Components Of An Air Compressor

To comprehend the functioning of an air compressor, it’s crucial to familiarize yourself with its key components. Here are the essential parts of an air compressor:

- Motor: The motor is responsible for powering the compressor and driving its operation.

- Air tank: The air tank serves as a reservoir to store compressed air. It ensures a continuous supply of compressed air when the demand exceeds the immediate capacity of the compressor.

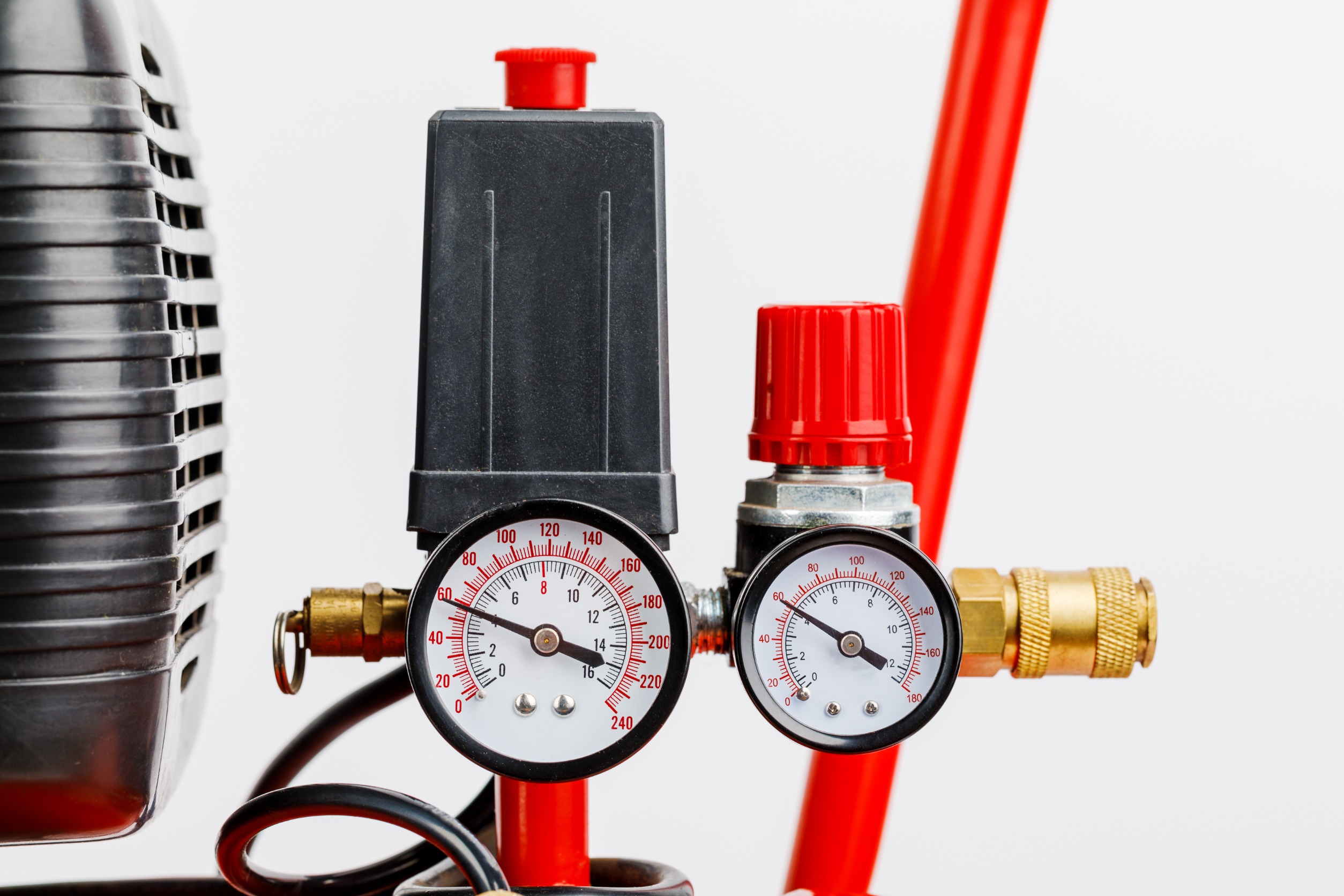

- Pressure switch: The pressure switch regulates the operation of the compressor by monitoring the air pressure inside the tank. It automatically turns the compressor on when the pressure drops below a certain threshold and shuts it off when the pressure reaches the desired level.

- Pressure relief valve: The pressure relief valve safeguards the air compressor by releasing excess pressure in the event of a malfunction or overheating.

- Compressor pump: The compressor pump is the heart of the air compressor. It draws in ambient air and compresses it to the desired pressure level.

How An Air Compressor Operates

Now that we have a basic understanding of the components, let’s explore how an air compressor operates:

- The motor powers the compressor pump, which starts drawing in atmospheric air through an intake valve.

- The compressor pump compresses the incoming air, causing its volume to decrease and its pressure to rise.

- The compressed air is then stored in the air tank, ready for usage whenever required.

- When the pressure inside the air tank drops below the set level, the pressure switch activates the motor, restarting the compressor pump to replenish the compressed air.

- Once the pressure reaches the desired level, the pressure switch deactivates the motor, shutting off the compressor.

- The cycle repeats whenever there is a demand for compressed air.

Basic Troubleshooting Steps

If your air compressor is not shutting off, here are some basic troubleshooting steps you can follow:

- Check the pressure switch: Inspect the pressure switch for any faults or incorrect settings. Ensure that it is properly calibrated and functioning as intended.

- Examine the unloader valve: The unloader valve is responsible for relieving the pressure inside the compressor pump when it shuts off. Make sure the unloader valve is not stuck or malfunctioning.

- Inspect for air leaks: Check for any air leaks in the system, including fittings, hoses, and connections. Even minor leaks can cause the compressor to run continuously.

- Verify tank pressure: Use a pressure gauge to confirm the actual pressure inside the air tank. Compare it with the pressure switch settings to ensure they align.

- Clean or replace air filters: Clogged or dirty air filters can restrict airflow, leading to continuous operation. Clean or replace them as needed.

By understanding the components, operation, and troubleshooting steps of an air compressor, you’ll be better equipped to identify and resolve the issue of a compressor that doesn’t shut off. Always prioritize safety and consult a professional if you are unsure or encounter complex problems.

Common Reasons Why An Air Compressor Won’T Shut Off

There can be several reasons why an air compressor might not shut off, such as a faulty pressure switch, a leak in the system, or a malfunctioning motor. If you encounter this issue, it’s important to inspect and troubleshoot these components to identify and resolve the problem.

If you’re experiencing a situation where your air compressor keeps running and doesn’t shut off as it should, you may be wondering what could be causing this issue. There are several common reasons why an air compressor won’t shut off, including:

Faulty Pressure Switch:

- The pressure switch is responsible for monitoring the air pressure in the tank and turning the compressor on and off accordingly. If the pressure switch is faulty, it may not be accurately detecting the pressure and signaling the compressor to shut off when the desired pressure is reached.

- The contacts in the pressure switch could be stuck in the closed position, preventing the switch from shutting off the compressor even when the pressure is high enough.

Leaking Check Valve:

- The check valve is designed to prevent air from flowing back into the compressor when the motor is not running. However, if the check valve is leaking, it can cause the air to flow back into the compressor, keeping it running even when the pressure reaches the desired level.

- A faulty check valve can be due to debris or dirt clogging the valve, causing it to remain open even when it should be closed.

Malfunctioning Unloader Valve:

- The unloader valve is responsible for releasing the pressure in the compressor’s cylinder head when the motor stops running. If the unloader valve malfunctions, it may not be releasing the pressure, causing the compressor to continue running.

- A broken or stuck unloader valve can prevent the normal release of air pressure, leading to the compressor not shutting off as it should.

Remember, it’s essential to address these issues promptly to prevent further damage to your air compressor and ensure its proper functioning. If you’re unsure about how to troubleshoot or fix these problems, it’s recommended to consult a professional or refer to the manufacturer’s manual for specific guidance.

Troubleshooting And Fixing An Air Compressor That Won’T Shut Off

If your air compressor refuses to shut off, troubleshooting and fixing the issue is crucial. Discover the reasons behind why your air compressor won’t shut off and find effective solutions to get it back on track.

If you’ve noticed that your air compressor is not shutting off properly, it’s important to address the issue promptly to prevent further damage or potential safety hazards. There are a few common culprits that could be causing this problem, and in this section, we will discuss how to troubleshoot and fix an air compressor that won’t shut off.

Step 1: Checking The Pressure Switch

The pressure switch plays a crucial role in regulating the pressure levels within the air compressor. If it is malfunctioning, it may not be able to detect when the desired pressure has been reached, causing the compressor to run continuously.

Here are the steps to check the pressure switch:

- Inspecting for damage or loose connections:

- Carefully examine the pressure switch for any signs of physical damage, such as cracks or frayed wires. Also, make sure that all connections to the switch are tight and secure.

- Testing the switch with a multimeter:

- Using a multimeter, you can measure the continuity of the pressure switch to determine if it is functioning properly. Follow the manufacturer’s instructions to connect the multimeter and perform the test.

Step 2: Inspecting The Check Valve

The check valve is responsible for preventing backflow of air from the receiver tank to the compressor pump when the unit is not running. A malfunctioning check valve can cause the compressor to continuously run. Follow these steps to inspect the check valve:

- Identifying leaks and blockages:

- Check for any visible leaks or blockages around the check valve. Inspect the valve thoroughly for any signs of wear or damage.

- Replacing a faulty check valve:

- If you discover that the check valve is faulty, it will need to be replaced. Consult your air compressor’s user manual or contact the manufacturer for the specific replacement instructions.

Step 3: Checking The Unloader Valve

The unloader valve is responsible for releasing trapped air from the compressor head when the unit shuts off. If the unloader valve is not functioning correctly, it can cause the compressor to continue running. Understanding the role and checking the unloader valve is essential:

- Understanding the role of the unloader valve:

- The unloader valve is designed to relieve the pressure built up in the compressor head when the unit shuts off. This allows for an easier start when the compressor turns back on.

- Cleaning or replacing the unloader valve:

- Inspect the unloader valve for any debris or clogs that may be affecting its performance. If necessary, clean the valve thoroughly. If the valve is damaged or worn beyond repair, it may need to be replaced.

By following these troubleshooting steps, you’ll be able to identify and fix the issues leading to your air compressor not shutting off. Remember to prioritize your safety and consult a professional if you’re unsure about any aspect of the troubleshooting or repair process.

Other Potential Causes And Solutions

Potential causes for an air compressor not shutting off could include a faulty pressure switch, leaky valves, or a malfunctioning motor. To resolve these issues, check and replace any defective components, ensure proper airflow and pressure, and consider consulting a professional if needed.

Air leaks in the system:

- Check for any leaks in the air compressor system by listening for hissing sounds or using a soapy water solution to identify bubbles.

- Tighten any loose fittings or connections to ensure a proper seal.

- Replace any damaged or worn-out seals, gaskets, or o-rings to eliminate leaks.

- Regularly inspect and maintain the hoses and pipes to ensure they are in good condition.

Inadequate tank size:

- Assess if the air compressor tank is undersized for the intended usage.

- Consider the demand of the air tools or equipment you are using and compare it to the air compressor’s capacity.

- If the tank size is insufficient, upgrade to a larger tank that can handle the desired workload.

- Keep in mind that a larger tank will allow the compressor to run less frequently, helping prevent overheating.

Electrical issues:

- Check the power source and make sure the air compressor is receiving proper voltage.

- Inspect the power cord for any damage or fraying.

- Verify that the circuit breaker or fuse is not blown by resetting or replacing it if necessary.

- Consider consulting a professional electrician to diagnose and fix any electrical issues.

Regular maintenance and preventive measures:

- Conduct routine maintenance on your air compressor, following the manufacturer’s guidelines.

- Clean or replace the air filter to ensure proper airflow and prevent debris from affecting the compressor’s performance.

- Drain the tank regularly to remove moisture and maintain optimal air quality.

- Lubricate moving parts to reduce friction and prolong the life of the compressor.

- Keep the compressor in a clean and well-ventilated area to prevent overheating.

Remember, addressing other potential causes such as air leaks, inadequate tank size, electrical issues, and regular maintenance can help diagnose and resolve the issue of an air compressor not shutting off. By following these tips and taking preventive measures, you can ensure the efficiency and longevity of your air compressor.

Frequently Asked Questions On Why Does My Air Compressor Not Shut Off

Why Does My Air Compressor Not Shut Off?

If your air compressor does not shut off, it could be due to a faulty pressure switch. Check the switch for any damage or loose connections. Another reason could be a leak in the system, causing the pressure to drop and the compressor to keep running.

Make sure to inspect all hoses and fittings for any leaks. Additionally, an issue with the motor or the compressor itself may also be causing the problem. It is recommended to seek professional assistance for further diagnosis and repair.

Conclusion

If you’re wondering why your air compressor won’t shut off, there are a few potential causes to consider. First, check the pressure switch to ensure it is functioning correctly and adjusted to the appropriate settings. Next, inspect the check valve for any obstructions or damage that may be preventing it from closing properly.

Additionally, make sure the unloader valve is working correctly and releasing pressure when necessary. It’s also important to check for any air leaks in the system, as these can cause the compressor to continuously run. Lastly, regular maintenance, including cleaning or replacing filters and lubricating moving parts, can help optimize the performance of your air compressor.

By troubleshooting these potential issues and taking necessary steps to resolve them, you can ensure that your air compressor shuts off as intended, allowing for efficient and safe operation.